200以上 minimum yield strength of steel 203421-Minimum yield strength of s355 steel

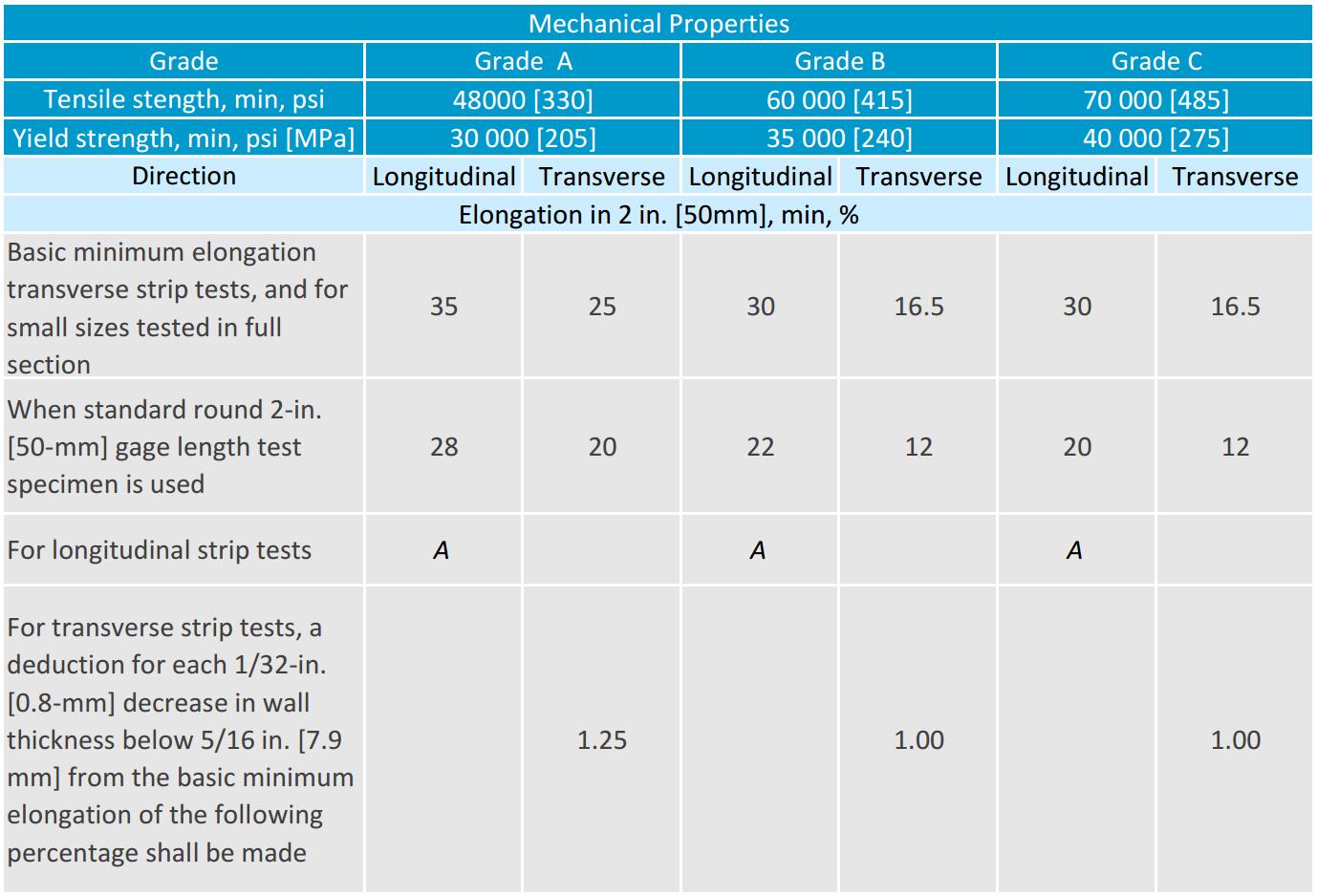

EN Technical delivery conditions for steel plate and sheet of high yield strength structural steel products in the quenched and tempered condition S Structural steel 460 Minimum yield strength (Reh) in MPa at 16mm;Minimum Yield Strength Steel Strength Category;The material is required to conform to a minimum average Charpy Vnotch impact value of 25 ftlb at 40°F (approximately 34 J at 4°C), as documented in the mill test report In addition, a maximum yield stress of 70 ksi (485 MPa) as well as a minimum yield stress of 50 ksi (345 MPa) applies

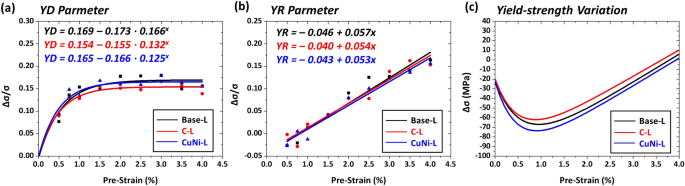

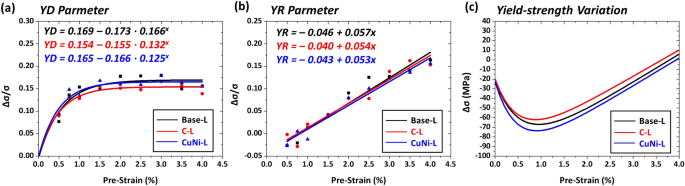

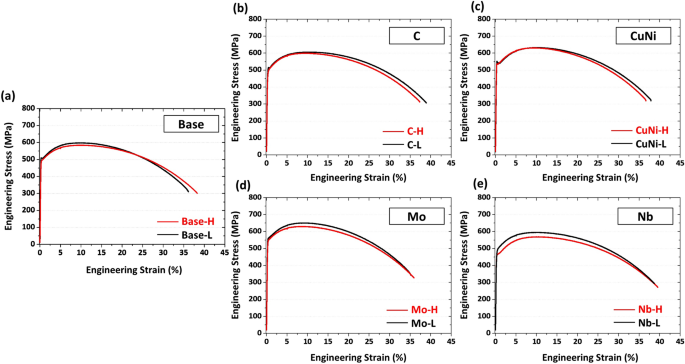

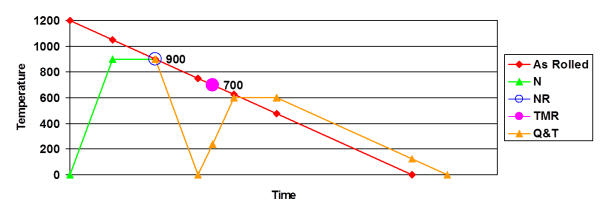

Effects Of Finish Rolling Temperature And Yield Ratio On Variations In Yield Strength After Pipe Forming Of Api X65 Line Pipe Steels Scientific Reports

Minimum yield strength of s355 steel

Minimum yield strength of s355 steel-Browse MS Cold Rolled Steel in the MST Steel Corp catalog including Item #,Item Name,Minimum Yield Strength,Steel Strength Category,Steel Finish MST Steel Corp is a Supplier and Processor of Steel Coils and Steel Sheets "Steel Coils & Sheets" ISO/TS MIQ Longitudinal Charpy Vnotch impacts temp not lower than °C

Steel Material Properties Steelconstruction Info

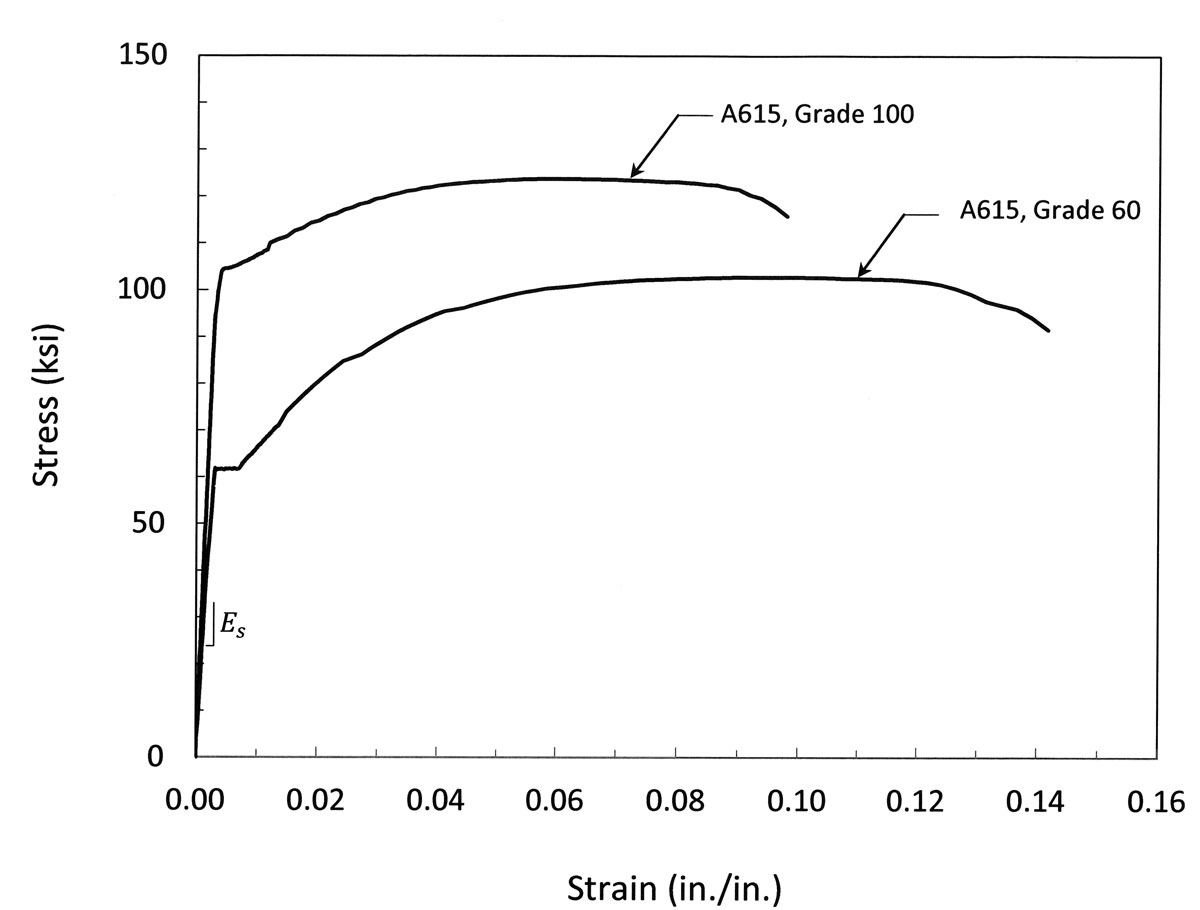

The yield strength of structural steel measures the minimum force required to create a permanent deformation in the steel The naming convention used in European Standard EN refers to the minimum yield strength of the steel grade tested at 16mm thick Structural Steel Grade at 16mmMinimum yield strength of 44,000 psi Minimum tensile strength of 70,000 to 90,000 psi 44W/300W is another mild steel plate grade specified within G4021 of the Canadian Standards Association (CSA) Most commonly referred to as 44W, or its metric equivalent 300W, this grade is commonly utilized in general fabrication and constructionYield Strength Fy (ksi) Tensile Strength Fu (ksi) Fu / Fy Minimum Elongation (%) in 2in Gage Length Carbon structural steel A36 36 50 161 23 A36 50 70 14 21 Highstrength lowalloy Structural steel 42 46 67 146 21 Low and intermediate tensile strength carbon steel plates A 24 4560 1 30 B 27 5065 185 28 C 30 5575 1 25 D

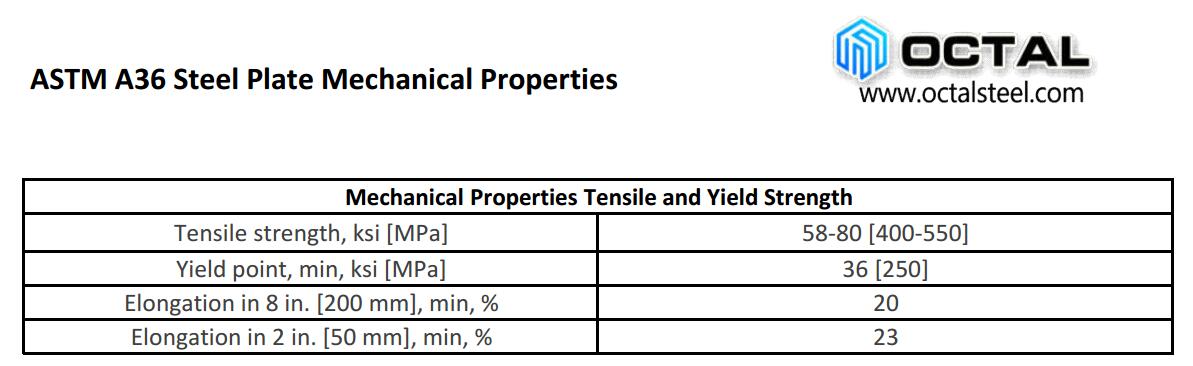

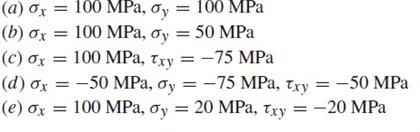

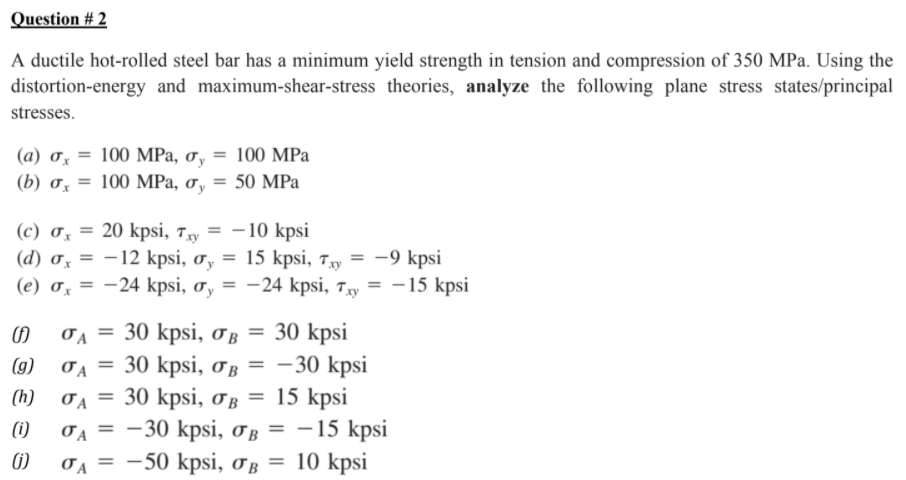

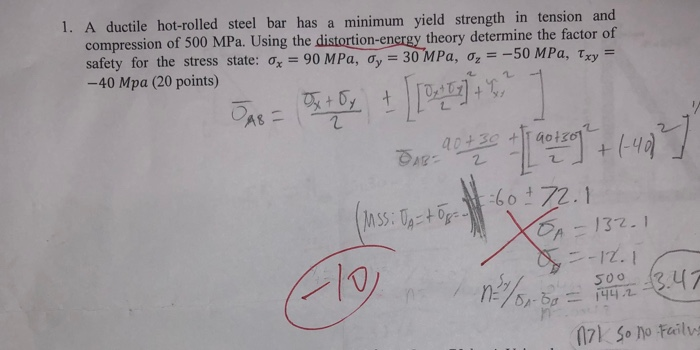

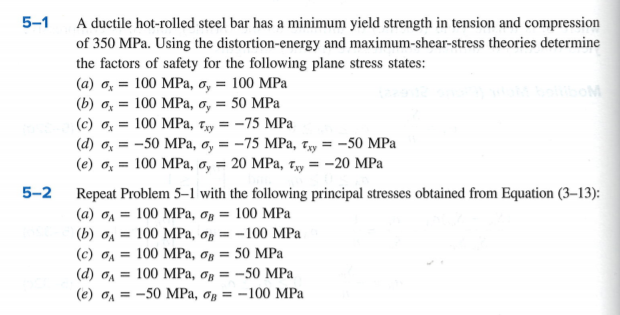

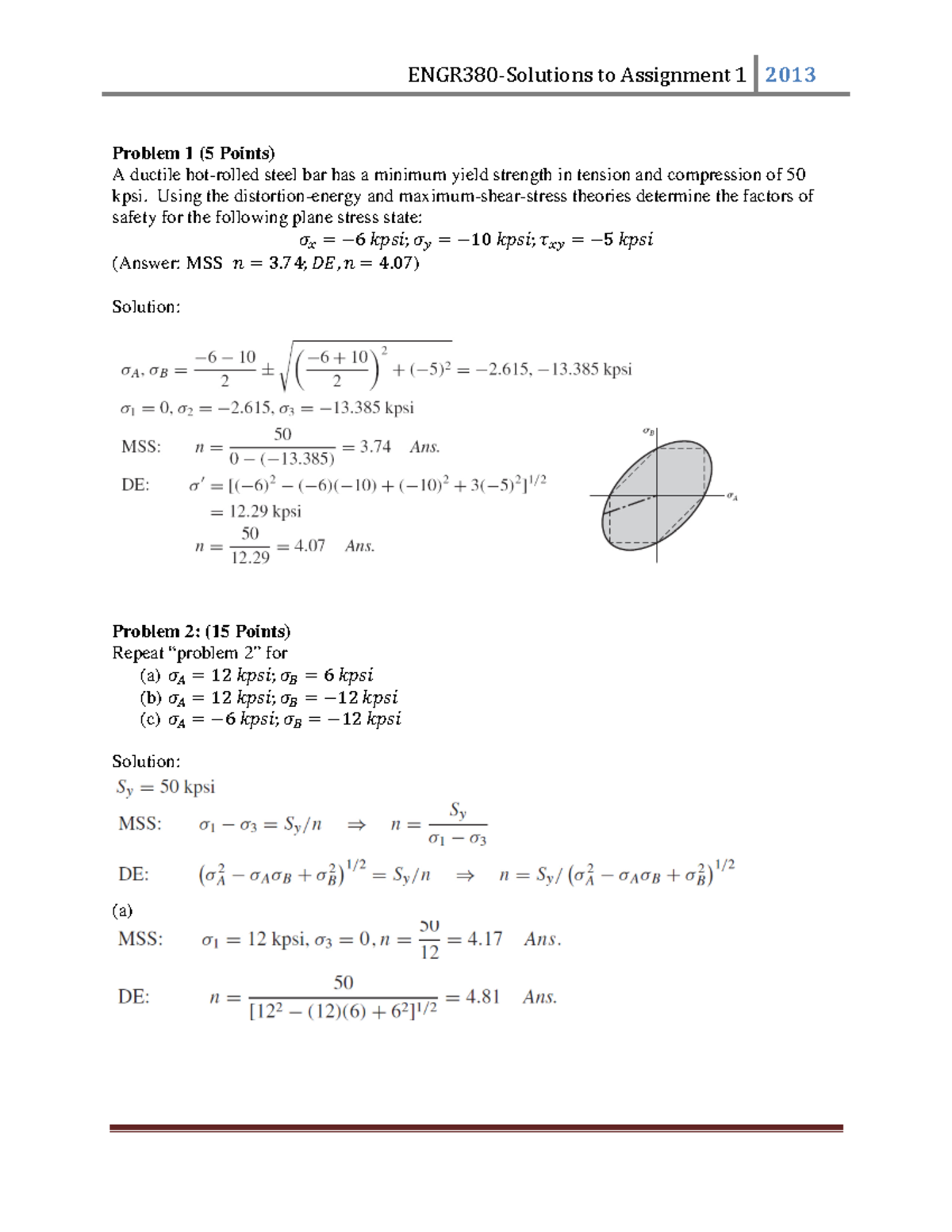

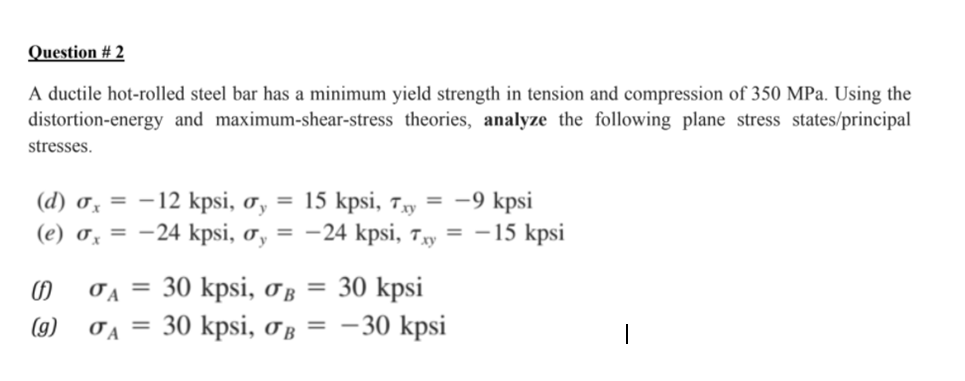

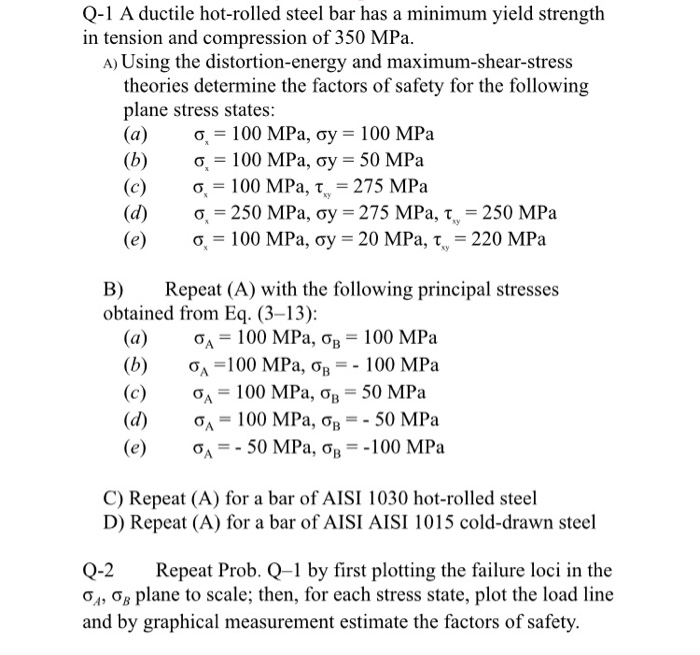

A ductile hot rolled steel bar has a minimum yield strength in tension and compression of 350 MPa Using the distortion energy and maximum shear stress theories Determine the factor of safety for following plane stress statesRail steel angles from Jersey Shore Steel possess a tensile strength minimum of at least 80,000 psi and a yield strength minimum of at least 50,000 psi Compare Rail Steel and Mild Steel Typical Rail Steel results have shown an average of at least 65,000 psi and a tensile strength of 111,000Yield strength, MPa (ksi), ≥ 250 (36) Thickness ≤ 0mm (8 in) 2 (32) Steel plates thickness > 0mm (8 in) Elongation, %, ≥ Plates and Bars in 0 mm (8 in) 23 Plates and Bars in 50 mm (2 in) Brinell hardness, HB Based on the conversion from tensile strength Charpy VNotch Impact Test, J ( ft·lbf), ≥ 27 ()

Different grades of steel will have different tensile and yield strengths It 's generally accepted and recommended by engineers that steel used for pallet rack have a minimum yield strength of 50,000 psi Most US manufacturers use steel rated from 50,000 to 55,000 psi (All Next Level FlexRack™ has a minimum of 55,000 psi)Deep Drawing Steel (DDS) N/A N/A MS LAH210Y310T 210 Megapascal (MPa) Minimum Yield Strength 210 MPa HighStrength LowAlloy (HSLA) MS LAH240Y330T 240 Megapascal (MPa) Minimum Yield StrengthWhat is fy and fu of steelyield strength and tensile strength according to yield strength steel is divided into two category 1) low/mild strength that is mild steel having yield strength is Fe250 which can rasist the force of stress of 250N/mm2 when applied on it tensile strength of mild steel is 410 mpa

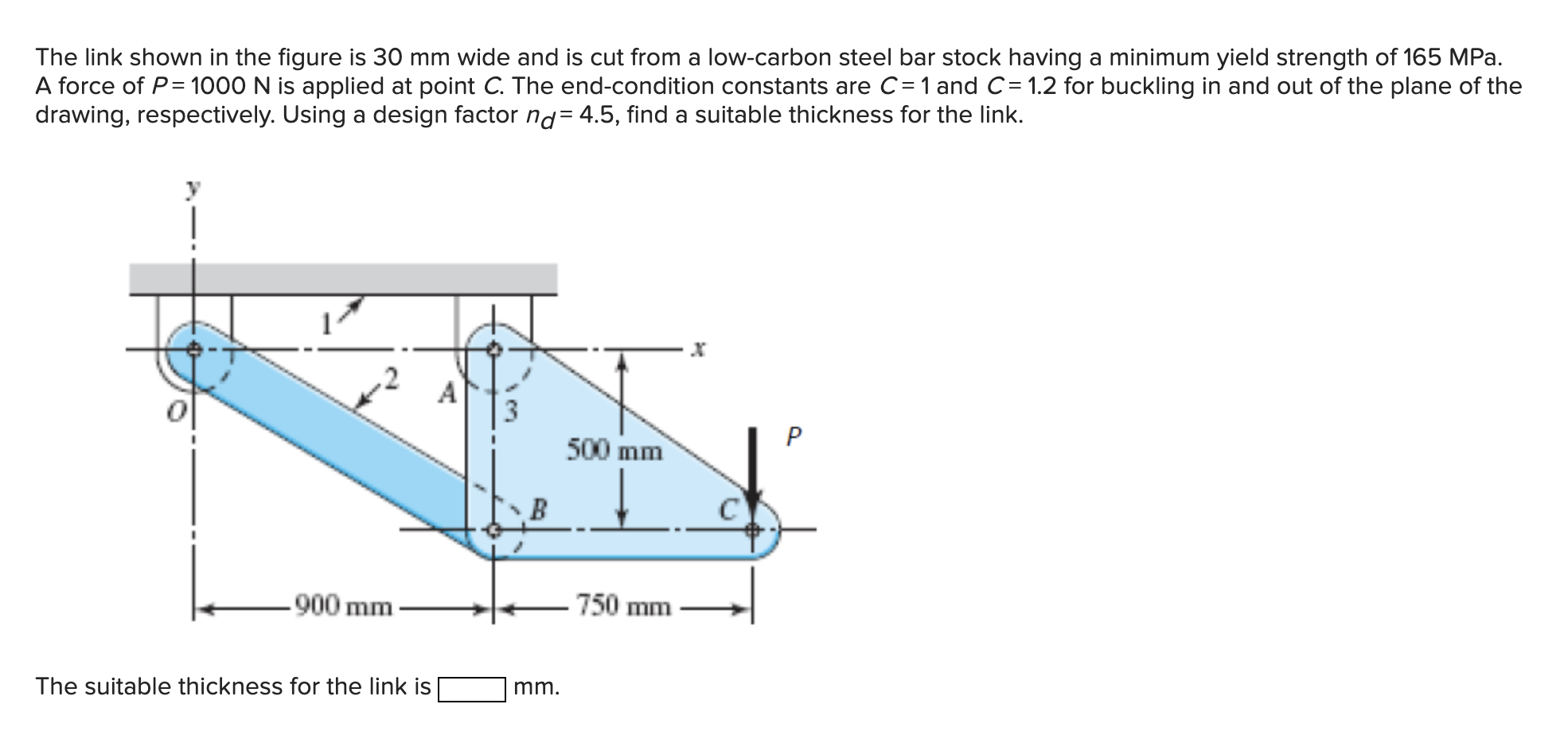

Solved The Link Shown In The Figure Is 30 Mm Wide And Is Chegg Com

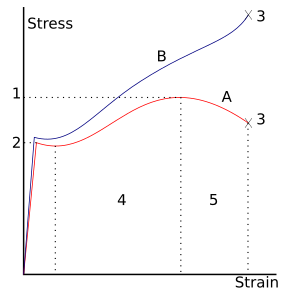

What Is The Basic Difference Between Yield Strength And Ultimate Strength For Any Elastic Material Quora

A36 a low carbon steel with good strength, formability that can be securely welded with a minimum yield strength of 36,000 PSI;In materials engineering, yield strength and tensile strength are two properties that can be used to characterize a material The main difference between yield strength and tensile strength is that yield strength is the minimum stress under which a material deforms permanently , whereas tensile strength describes the maximum stress that aGeneral purpose 42–50 63–70

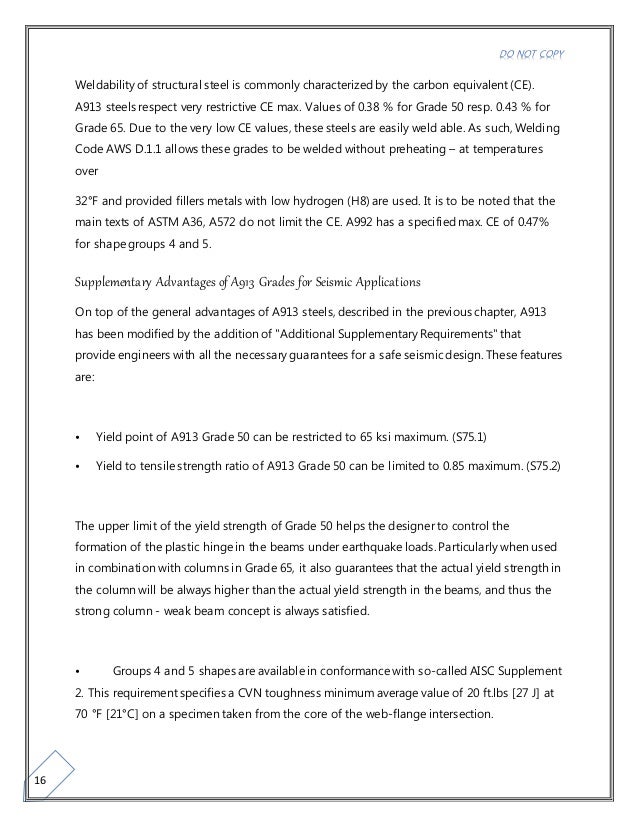

Steel Codes Used In Steel Structure 5th Semester Word Document

Astm A36 Steel Plate Completely Specifications You Should Know

Yield strength, MPa (ksi), ≥ 250 (36) Thickness ≤ 0mm (8 in) 2 (32) Steel plates thickness > 0mm (8 in) Elongation, %, ≥ Plates and Bars in 0 mm (8 in) 23 Plates and Bars in 50 mm (2 in) Brinell hardness, HB Based on the conversion from tensile strength Charpy VNotch Impact Test, J ( ft·lbf), ≥ 27 ()The values shown for hotrolled and cold drawn steel are estimated minimum values which can usually be expected in the size range of 3/4 to 11/4 in A minimum value is roughly several standard deviations below the arithmetic mean The values shown for heattreated steel are socalled typical values A typical value is neither the mean nor the minimumYield strength is the most common property that the designer will need as it is the basis used

Advanced High Strength Steel Ahss Definitions Worldautosteel

Solved A Metal Object Is Required To Have A Yield Strengt Chegg Com

Steel base Guaranteed Typical Range Guaranteed Maximum Percent Longitudinal tensile Carbon (C) 0 Yield strength, minimum ksi 33 3351 Phosphorus (P) 010 Tensile strength, minimum ksi 45 4564 Manganese (Mn) 135 Elongation in 2 inch, minimum % 37 Sulfur (S) 004According to ASTM A653 standards, mild hotdip galvanized steel must have a minimum yield strength of 36,300 PSI To find the actual yield strength of your pipe, contact the manufacturer or an engineerYield Strength, Modulus of Elasticity, Ultimate Strength of Selected Materials A straight line is drawn through Point (D) at the same slope as the initial portion of the stressstrain curve The point of intersection of the new line and the stressstrain curve is projected to the stress axis

Tesile Property Of Pipe Drilling Formulas And Drilling Calculations

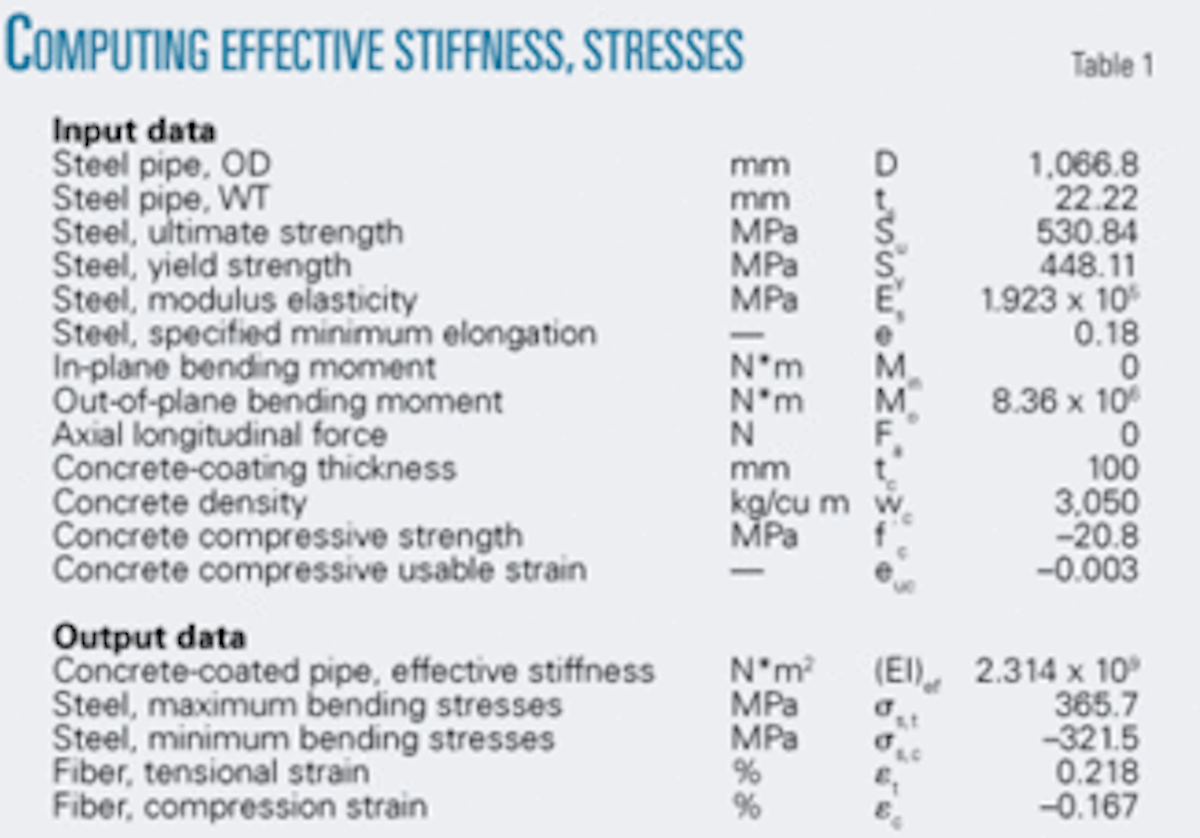

New Method Sets Concrete Coating S Effect On Pipeline Stiffness Stress Oil Gas Journal

The yield strength of these four grades of steel (not less than 235N/mm^2) and the tensile strength (400~5N/mm^2) are the same , but the impact energy at different temperatures is different;Yield Strength, Modulus of Elasticity, Ultimate Strength of Selected Materials A straight line is drawn through Point (D) at the same slope as the initial portion of the stressstrain curve The point of intersection of the new line and the stressstrain curve is projected to the stress axisUnderstanding the actual yield strength of a metal is just half the story The other half are the engineers who determine the required yield strength needed for steel, depending on the purposes for which it's being used This is the minimum yield strength needed for a project

1 A Ductile Hot Rolled Steel Bar Has Minimum Yield Strength Of 360 Mpa Using The Homeworklib

Astm A615 Reinforcement Bar A615 60 Grade Steel

Group II designates intermediate strength steels with specified minimum yield strengths of over 40 ksi (280 MPa) through 52 ksi (360 MPa) Carbon equivalent ranges are up to 045% and higher, and these steels require the use of low hydrogen welding processesTensile / yield strengths and ductilities for some of the plain carbon and low alloy steels are4130 (Chromoly) Normalized Alloy Steel Ultimate Tensile Strength, psi 97,0 Yield Strength, psi 63,100 Elongation 255% Minimum Properties Rockwell Hardness B92 4130 (Chromoly) Annealed Alloy Steel Tensile Strength, psi 81,0 Yield Strength, psi 52,0 Elongation 2% Minimum Properties Rockwell Hardness B Iron (Fe) 973 92%

Allowable Stress For Piping Materials As Per Asme 1 3

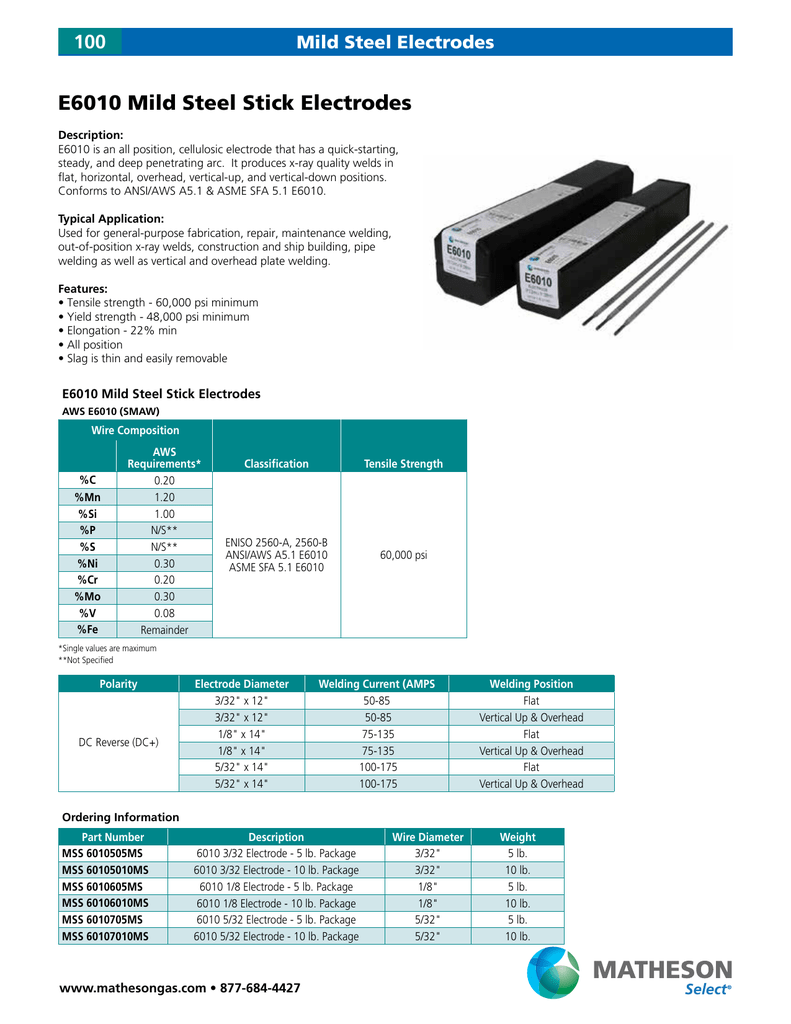

E6010 Mild Steel Stick Electrodes Manualzz

Highstrength hull structure steels are classified according to their minimum yield strength, and each strength grade is classified into A, D, E, and F4A steel with a minimum tensile strength of 70,000 PSI that is generally used in pressure vessels and boilersSteel Condition Tensile strength, MPa (ksi), ≥ Yield strength, MPa (ksi), ≥ Elongation in 50 mm (2 in), ≥ Reduction in area, %, ≥ Hardness, HB, ≤ 4340 Normalized at 870 °C (1600 °F) 12 (186) 862 (125) 122 363 363 Annealed at 810 °C (1490 °F) 745 (108) 470 (68) 2 500 217 Oil quenched from 800 °C (1475 °F) and tempered at 540 °C (1000 °F)

Flexural Behavior Of Beams Reinforced With Steel Bars Exceeding The Nominal Yield Strength

Results For A Yield Strength Of Steel Download Scientific Diagram

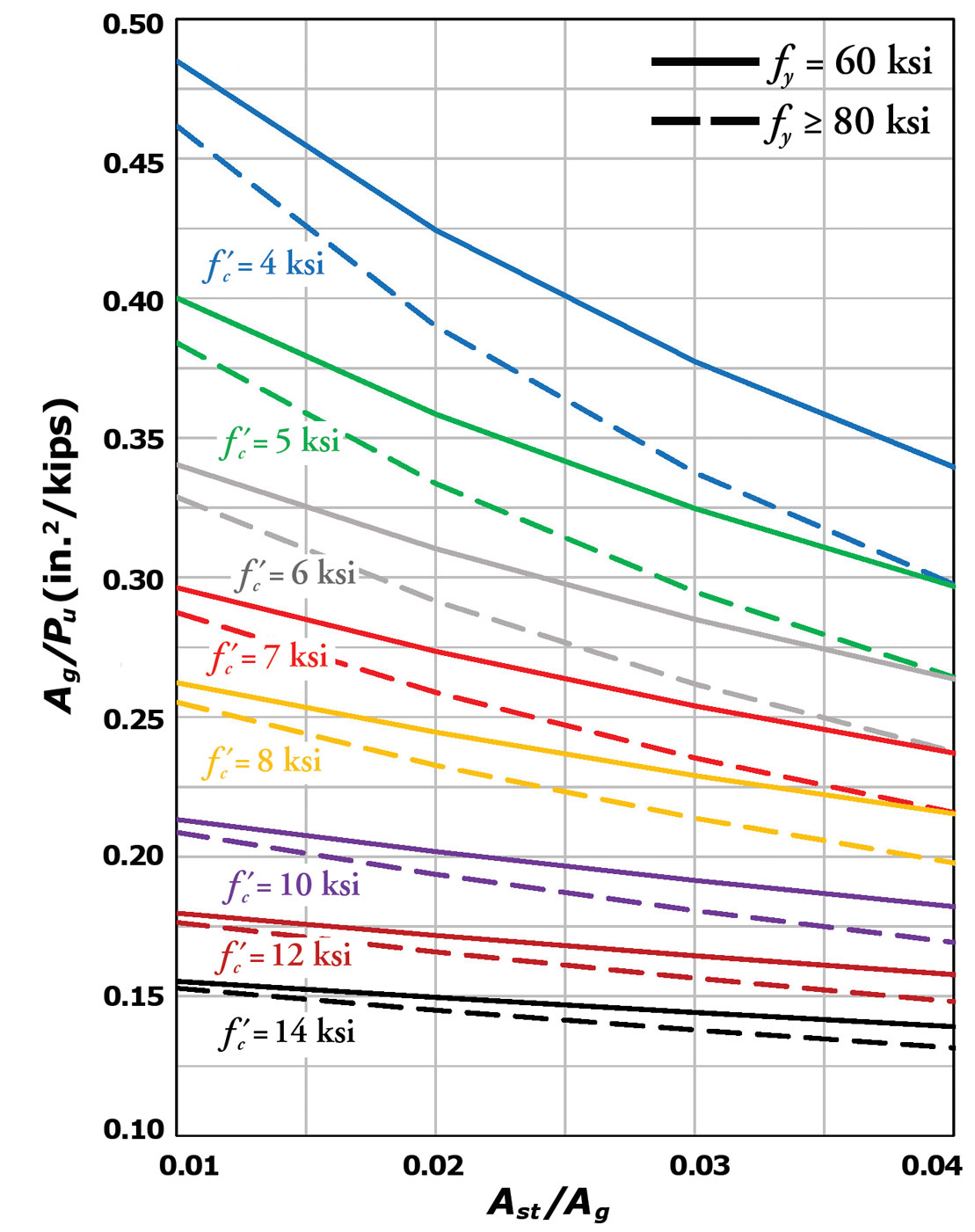

The minimum yield strength is the key property of steel used in pipeline design See FigureStresses based on structural steel conforming to the ASTM 21 Standard, which had a minimum required tensile strength of 60,000 psi and a minimum required yield point of 30,000 psi The AISC Code of Standard Practice, which followed in 1924, included section properties and load tables of 24in standard beams produced at the timeMPa (Yield) *Guaranteed Minimum Yield 350 MPa Grade 350 is a Higher Strength Structural Carbon Steel with a nominal yield strength of 350 MPa It can also be easily cut, welded and formed It is popular when applications require higher strength such as lifting equipment or Transport Chassis Typical Applications include Lifting Lugs;

Minimum Yield Strength An Overview Sciencedirect Topics

Yield Strength Strength Mechanics Of Materials Engineers Edge

The material is required to conform to a minimum average Charpy Vnotch impact value of 25 ftlb at 40°F (approximately 34 J at 4°C), as documented in the mill test report In addition, a maximum yield stress of 70 ksi (485 MPa) as well as a minimum yield stress of 50 ksi (345 MPa) appliesTensile strength of steel will show us how much tensile stress the steel can withstand until it leads to failure in two ways ductile or brittle failure Ductile failure – think of this as the preliminary stage of failure, where it is pushed beyond the yield point to permanent deformationStrenx® P700 is a pressure vessel steel with minimum yield strength of 670 700 MPa

Material Properties

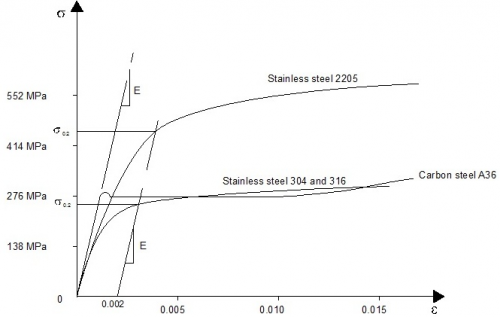

Stainless Steel Properties Grades And Applications Fractory

Strength Yield strengtYield strength is the most common property that the designer will need as it is the basis used for most of the rules given in design codesIn European Standards for structural carbon steels (including weathering steel), the primary designation relates to the yield strength, eg S355 steel is a structural steel with a specified minimum yield strength of 355 N/mm²S355 Yield Strength S355 is named based on it's minimum yield strength of 355 Mpa (N/mm2), However the yield strength reduces when you go up in thickness above 16 mm for flat products & hollow sections Here is the table showing reduction in yield strength based on thickness Up to 16 mm 355 Mpa 16 mm < t ≤ 40 mm 345 MpaA higher strength steel with a minimum yield of 50,000 PSI and increased corrosion resistance;

Steel Reinforcement For Concrete Masonry Ncma

Characteristic Strength Of Materials Characteristic Load Or Ultimate Load

*Guaranteed Minimum Yield 250 MPa Grade 250 is a Moderate structural steel grade with a nominal yield strength of 250 MPa it used in a wide range of general applications Grade 250 is readily welded and formed and can be processed by Laser, HiDef Plasma or Oxy machinesHighstrength hull structure steels are classified according to their minimum yield strength, and each strength grade is classified into A, D, E, and F4 according to their impact toughness The yield strength of A32, D32, e32 and F32 is not less than 315N/mm^2, and the tensile strength is 440~570N/mm^2Since many long distance transmission pipelines are designed to have a steel hoop stress of 80% of specified minimum yield strength (SMYS) at Maximum allowable operating pressure MAOP, this means that the steel is stressed to SMYS and above during the testing, and test sections must be selected to ensure that excessive plastic deformation does

Step By Step Please A Ductile Hot Rolled Steel Bar Has Minimum Yield Strength Of 360 Homeworklib

Probabilistic Tensile Strength Analysis Of Steel Strips In Mse Walls Considering Corrosion Journal Of Geotechnical And Geoenvironmental Engineering Vol 145 No 5

Specified Minimum Yield Strength (SMYS) means the specified minimum yield strength for steel pipe manufactured in accordance with a listed specification This is a common term used in the oil and gas industry for steel pipe used under the jurisdiction of the United States Department of TransportationMinimum yield strength of 44,000 psi Minimum tensile strength of 70,000 to 90,000 psi 44W/300W is another mild steel plate grade specified within G4021 of the Canadian Standards Association (CSA) Most commonly referred to as 44W, or its metric equivalent 300W, this grade is commonly utilized in general fabrication and constructionGeneral purpose 36 58–80 A529 Carbonsteel plates and bars 05" thick 42 60–85 Highstrength steels 42 Highstrength lowalloy shapes, plates, and bars;

Minimum Yield Strength An Overview Sciencedirect Topics

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

MS CR01 Commercial Steel Type B (CSB) N/A N/A MS CR02 Forming Steel Type B (FSB) N/A N/A MS CR04 Deep Drawing Steel (DDS) N/A N/A MS CR05Structural steels and minimum tensile properties Form Class ASTM Designation Product Yield, ksi Strength, ksi Carbon steels A36 Carbonsteel shapes, plates, and bars;Minimum Tensile Strength and Yield Strength of Pallet Rack Different grades of steel will have different tensile and yield strengths It 's generally accepted and recommended by engineers that steel used for pallet rack have a minimum yield strength of 50,000 psi Most US manufacturers use steel rated from 50,000 to 55,000 psi (All Next

Yield Strength Strength Mechanics Of Materials Engineers Edge

What Is The Ultimate Tensile Strength And Yield Strength Of Mild Steel And Hysd Bar Quora

S355 is named based on it's minimum yield strength of 355 Mpa (N/mm2), However the yield strength reduces when you go up in thickness above 16 mm for flat products & hollow sections Here is the table showing reduction in yield strength based on thickness Up to 16 mm 355 Mpa 16 mm < t ≤ 40 mm 345 MpaStrength Grade 40 Grade 60 Grade 75 Minimum Yield Strength 40,000 Psi 60,000 Psi 75,000 Psi Maximum Yield Strength 60,000 Psi 90,000 Psi 1,00,000 PsiMinimum yield of 34 ksi A514 T1® This is a heattreated steel that offers high strength capabilities, weldability, and has few preheat requirements Used in construction, it provides excellent durability in subzero temperatures A572 GR 50 This steel has a 50,000 psi minimum strength level offering a combination of high strength along with

Steel Material Properties Steelconstruction Info

113 Questions With Answers In Yield Strength Science Topic

Specified Minimum Yield Strength ( SMYS) means the specified minimum yield strength for steel pipe manufactured in accordance with a listed specification 1 This is a common term used in the oil and gas industry for steel pipe used under the jurisdiction of the United States Department of Transportation It is an indication of the minimum stress a pipe may experience that will cause plastic (permanent) deformationSpecified Minimum Yield Strength (SMYS) means the specified minimum yield strength for steel pipe manufactured in accordance with a listed specification 1This is a common term used in the oil and gas industry for steel pipe used under the jurisdiction of the United States Department of TransportationIt is an indication of the minimum stress a pipe may experience that will cause plasticStructural steels and minimum tensile properties Form Class ASTM Designation Product

Effects Of Finish Rolling Temperature And Yield Ratio On Variations In Yield Strength After Pipe Forming Of Api X65 Line Pipe Steels Scientific Reports

Grades Of Steel Used Cagecraft

The minimum yield and tensile strengths are 33 ksi and 52 ksi, respectively All references to bolts or machine bolts (MBs) are for structural quality through bolts (not lag screws or carriage bolts) equal to or better than ASTM Standard A307, Grade A Unless otherwise noted, bending steel in the field may cause fractures at the bend line

Answered Question 2 A Ductile Hot Rolled Steel Bartleby

Q Tbn And9gcrhvogkniaf5aix Yv5viz777uqklm0zjg52gijgphwvl7khodo Usqp Cau

Pin On Offering Steel Plates Stock Top 1

Q235d Carbon Steel Tensile Strength Carbon Steel Steel Plate Steel

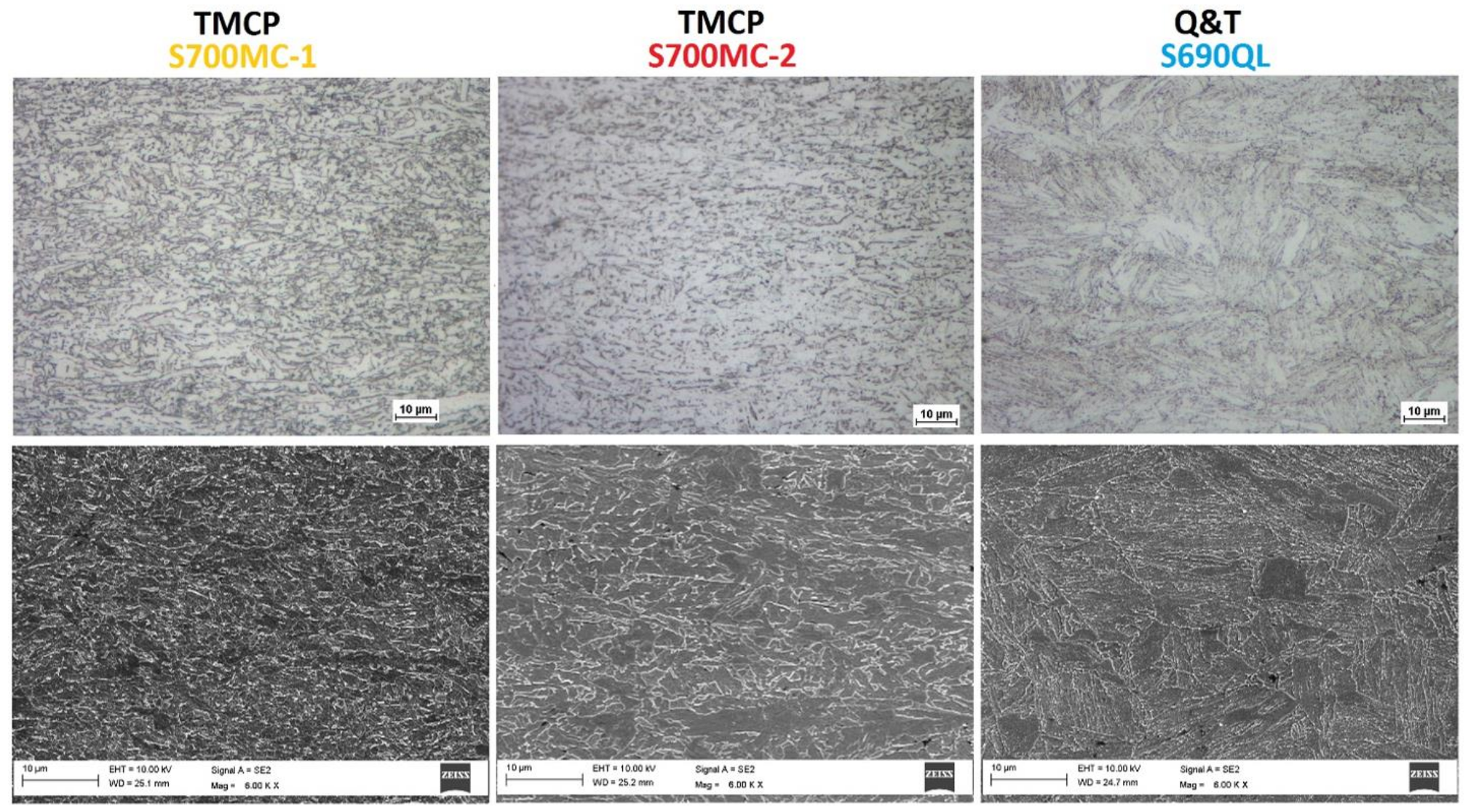

Applied Sciences Free Full Text Mag Welding Tests Of Modern High Strength Steels With Minimum Yield Strength Of 700 Mpa Html

Drill Pipe

Ultimate Tensile Strength Wikipedia

Www Aisc Org Globalassets Aisc Manual 15th Ed Ref List Specification For The Design Of Steel Hollow Structural Sections Pdf

Tesile Property Of Pipe Drilling Formulas And Drilling Calculations

Pdf Microstructure And Mechanical Properties Of High Strength Steel Welding Consumables With A Minimum Yield Strength Of 1100 Mpa

Interactive Minimum Yield Strength Magazines Online Minimum Yield Strength Magazine Publishers At Fliphtml5 Com

Yield Strength Of Steel

High Tensile Steel An Overview Sciencedirect Topics

What Is Fe 415 In A Steel Structure Quora

Astm A106 Grade B Pipe Sepcification Asme Sa106 Gr B Octal Steel

Yield Strength Strength Mechanics Of Materials Engineers Edge

What Is The Difference Between Tensile And Yield Strength Quora

Structure Magazine New Trends In Reinforcing Steel High Strength Reinforcing Bars

Steel Material Properties Steelconstruction Info

Target Material Specifications For Hsb800 And Hsa800 Steels Download Table

Solved 1 A Ductile Hot Rolled Steel Bar Has A Minimum Yi Chegg Com

Table Of Material Properties For Structural Steel S235 S275 S355 S4

Mohupa

Minimum Yield Strength An Overview Sciencedirect Topics

Stress Strain Curves Of High Strength Steels With Approximately The Download Scientific Diagram

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

.jpg)

High Yield Steel Properties And Capacities

Steel Structure Buildings Warehouse Modular Container House Pre Engineered Steel Structure Cold Storage Aot Steel Structure Buildings

Hot Rolled Flat Products Made Of High Yield Strength Steel For Cold Forming Flinsa

Structure Magazine New Trends In Reinforcing Steel High Strength Reinforcing Bars

Steel Properties At Low And High Temperatures Total Materia Article

Yield Strength Strength Mechanics Of Materials Engineers Edge

A Ductile Steel Bar Has A Minimum Yield Strength Of 50 Ksi Using The Mohr Circle And Determine Maximum Shear Stress And Principal Stresses For A And B Plane Stress States

Download Asme 1 8 Gas Transmission And Distribution Piping Systems Paktechpoint

1

Effects Of Finish Rolling Temperature And Yield Ratio On Variations In Yield Strength After Pipe Forming Of Api X65 Line Pipe Steels Scientific Reports

1

Minimum Yield Strength 345 Mpa Steel Conical Steel Utility Poles 25m Electrical Power Pole

Faizan Steel Deformed Steel Bars Grade 60 Astm A615 A615m Faizan Steel Is One Of The Largest Manufacturers Of Deformed Steel Bars In Pakistan These Bars Comply With Astm A615 American Standards

Probabilistic Tensile Strength Analysis Of Steel Strips In Mse Walls Considering Corrosion Journal Of Geotechnical And Geoenvironmental Engineering Vol 145 No 5

.jpg)

Structural Steel S235 S275 S355 Chemical Composition Mechanical Properties And Common Applications

Mild Steel Grades And Relevant Properties Download Table

Flexural Behavior Of Beams Reinforced With Steel Bars Exceeding The Nominal Yield Strength

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

Stainless Steel Alloys Comparsion Chart Annealing Metallurgy Ultimate Tensile Strength

Www Integritystainless Com Wp Content Uploads 16 07 Nas Hr Grade 316 316l Pdf

Answered A Ductile Hot Rolled Steel Bar Has A Bartleby

Reinforcing Material Charectristic Strength And Types Of Steel Reinforcement

Steel Properties At Low And High Temperatures Total Materia Article

Seminar Assignments Answers To Assignment 1 Studocu

How To Get High Quality Carbon Steel Flanges Www Steeljrv Com

Sheet Pile Steel Grades By Hirnbock Stabau At A Glance

How Come The Yield Strength Is Greater Than Tensile Strength When Testing A Steel Specimen Quora

Yield Engineering Wikipedia

What Is The Difference Between Tensile And Yield Strength Quora

Solved A A Steel Component Has A Minimum Yield Strength Chegg Com

Cold Formed Steel Wikipedia

Steel Material Properties Steelconstruction Info

Www Cmetals Com Wp Content Uploads 03 Galvanized Steel Grade Data Sheets Pdf

Pipe Body Properties Catalogue

Minimum Yield Strength An Overview Sciencedirect Topics

Aisi 4130 Steel Pipe Heat Treated To 75 Ksi Minimum Yield Strength For Sour Service Buy 4130 Steel Pipe Aisi 4130 Steel Pipe 75 Ksi Min Yield Strength Pipe Product On Alibaba Com

Grade 65 15m Steel Power Pole 450mpa Yield Strength For Heavy Tension Steel Structures For Sale Steel Power Pole Manufacturer From China

Answered A Ductile Hot Rolled Steel Bar Has A Bartleby

Flexural Behavior Of Beams Reinforced With Steel Bars Exceeding The Nominal Yield Strength

Http Www Iacs Org Uk Download 6374

Stainless Steel Alloys Comparsion Chart Litz Wire Ustc Pages 1 3 Flip Pdf Download Fliphtml5

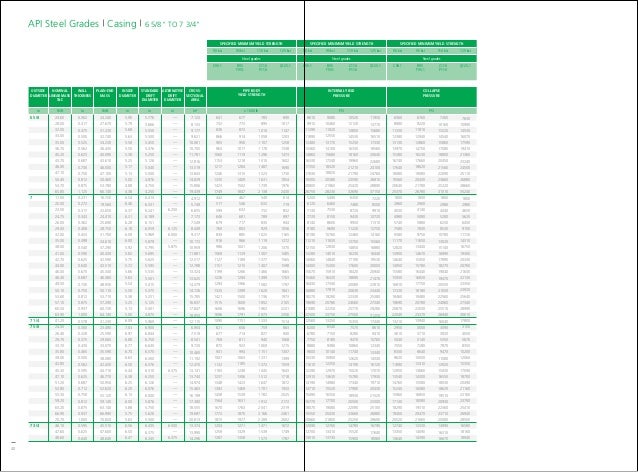

Casing Design Theory And Practice Material Properties Definition Drilling Manual

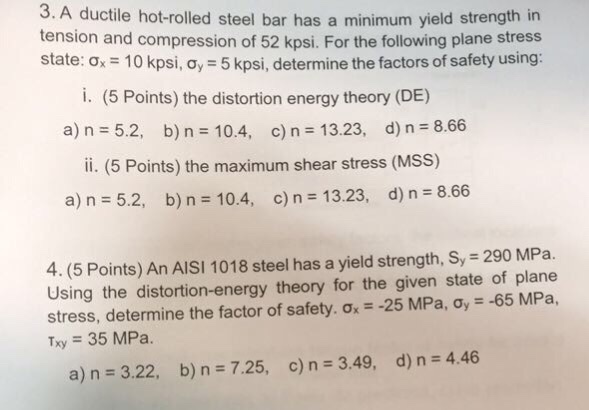

Solved 3 A Ductile Hot Rolled Steel Bar Has A Minimum Yi Chegg Com

Q Tbn And9gctkrzf52tulw Hck4iec8kqmmvrheff2kzrugh6dmtmgku6pybl Usqp Cau

Material Properties

Q345 Substation Steel Structures Minimum Yield Strength 345mpa 500kv

Failures Related To Api 5ct High Strength Steels Gate Energy

Solved Q 1 A Ductile Hot Rolled Steel Bar Has A Minimum Y Chegg Com

コメント

コメントを投稿